The great thing is that our technology works simultaneously in research and in practice. Any progress we make in development is directly used for basic research in the laboratory next door.

We did it! A few weeks ago, we officially established Midel Photonics GmbH – a laser technology startup, developing innovative solutions for beam shaping.

More than two years ago – at a party at my flat, late at night – I asked my co-founder Christian Wahl if he would be interested building a laser technology company with me. He was hooked with the idea and during the following weeks we made plans. We finally decided to take our chances. During my PhD I had developed a new method using micro-delamination (Midel) to structure laser mirror surfaces and we decided to transfer this technology to industry. Looking back, I can say that we had no idea what it actually meant, but the first step is chasing your dreams.

The entrepreneurial team grows

At that time we both were postdocs at the Institute of Applied Physics at the University of Bonn. We were involved in ongoing research projects, supervising students and doctoral candidates, as well as teaching. For us, founding a startup meant doing it our way and being our own bosses. We figured that we needed more opportunities for self-determination. So, we took the chance to apply for an open call grant in ML4Q. Under the project name MidelQ, we proposed an improvement of the structuring method for the project goals of ML4Q and a proof-of-principle for the use of the technology for industry.

We were able to convince the board and so Christian and I became leaders of our own project. At this time, Frederik Wolf joined our small team. He had just finished his bachelor’s thesis in the neighboring lab. He struck us as extremely ambitious and talented. He didn’t hesitate to join us alongside his master studies. It quickly became clear that he would be our third co-founder.

Midel Photonics founders Christian Wahl, David Dung, Christopher Grossert and Frederik Wolf; Image: Timo Heepenstrick

ML4Q Open Call funding as a stepstone

We used the open call funding to implement our ideas and we were able to show that the technology could in principle be used for laser beam shaping, the so-called proof-of-principle was achieved.

In my opinion, achieving a proof-of-principle in a university spin-off project is one of the big decision points in a personal career. You know that the idea could work, suspect that there are still countless hurdles ahead, and ask yourself: are you bold enough to take this path consistently?

“Consistently” means realizing that you have to leave the academic and sheltered environment behind, as the objective of a company differs significantly from that of a university. If you decide to spin off a company, you need to find partners in your new environment and make sure you have a strategy to get the resources you need. This is where politics can help to provide opportunities with so-called technology transfer programs. This puts the often young researchers in a position to develop an industrial prototype and test it in use (proof-of-concept). Once this bridge has been built with public money, it is then typically possible to go to market with private money and successively develop the company.

There is still limited funding in Germany for tech-transfer and the competition among the many great ideas is extremely high. Nevertheless, we believed in our potential and did our homework: Expanding the skillset of the team with our fourth co-founder Christopher Grossert; presenting our venture to over 20 international laser companies; getting written letters-of-interest; analyzing the market & competition; developing an initial business plan with detailed financial planning; applying & participating in the High-Tech.NRW business accelerator program; building industry and business contacts.

Those were intense months including after-work and weekend sessions, but in the end the application for our dream stood: An EXIST transfer-of-research grant application – the German flagship of technology transfer funding. The work paid off: The jury was enthusiastic about our plan and the four of us young applicants won 750.000Eur to develop an industrially usable prototype within 18 months based on the proof-of-principle – Midel Photonics was born!

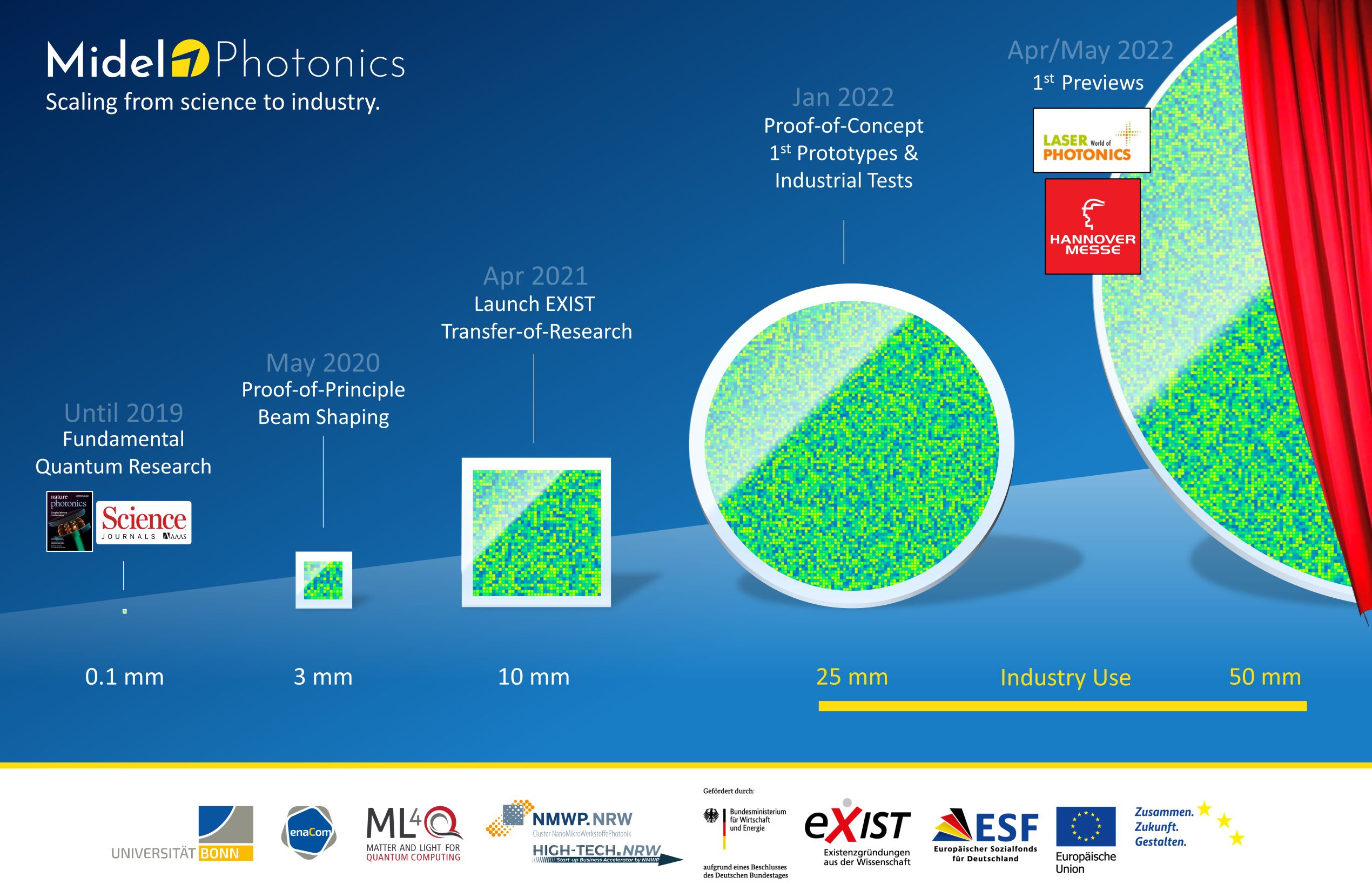

The MidelPhotonics evolution from fundamental quantum research over proof-of-principle work until the accomplishment of the proof of concept and the launch of first previews at renowned tech fairs; Image: David Dung

The product

Midel Photonics is all about manufacturing beam shapers. In our case, these are surface-structured laser mirrors that convert laser beams in their geometric shape using the principle of diffraction. For example, a round laser beam can be converted into a square or ring-shaped beam. In addition, it is also possible to divide the beam into a large number of beams. Although there are existing solutions on the market, ours is much faster to produce and can be tailored to customer requirements. This will enable a new generation of highly adapted lasers for material processing and a more efficient production of the future.

To make this a reality, we used the past 14 months, to scale the structured mirror size from tiny 0.1mm diameters for basic research to 50mm diameters. With this 250.000x scale-up in area, we are now manufacturing beam shapers in industrial size. This progress was accompanied by an enormous increase in speed, a deep understanding of the necessary microstructure patterns for beam shaping, and fully automated production. We have already successfully tested the first prototypes with our industrial partners proofing compatibility in the multi-kilowatt laser power segment.

This fast progress would not have been possible without a few key aspects: The first is project management. I’m not talking about rigid project plans or tons of overhead. We started using some modern and dynamic tools to make our work structured, agile and transparent. Along the way we learnt what worked best for us and that gave us a lot of drive. I can only recommend everyone to take a few courses on these topics during their studies. At some point you realize that resources are very limited. In our case, time is the most valuable of all and this forces us to prioritize over and over again. The second aspect is the team. Any project is only as successful as the people behind it, or more precisely, how successfully people work together. That’s why we strengthened our team awareness right from the start and established formats such as retrospectives. That’s fun and at the same time the team gets stronger and stronger.

Finally, I am proud. “We did it!”. As physicist and technology enthusiast, the chance to bring a technology into the industry from the ground up and build a life on it is a once-in-a-lifetime opportunity. I am glad I took it.

About David

(c) Barbara Frommann

Dr. David Dung is co-founder and managing partner of Midel Photonics. In April 2021 he and his three co-founders were awarded with an EXIST transfer-of-research grant of the federal ministry of economics. Before, he worked as Junior PI on the ML4Q open call project MidelQ. David studied physics in Bonn and got his PhD in the field of experimental laser and quantum physics.